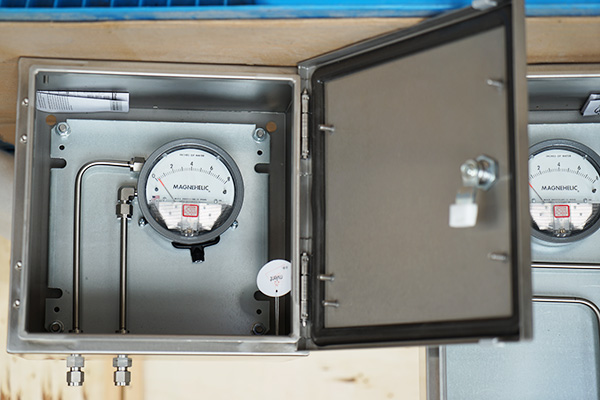

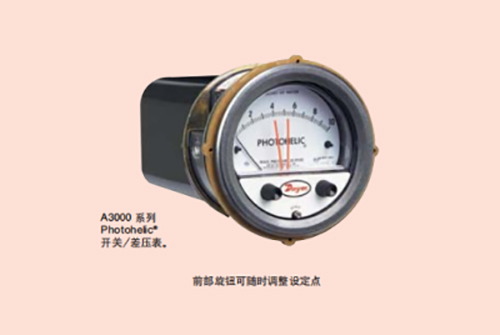

DWYER differential pressure switch function principle and installation method? Widely used in air conditioning and clean rooms, intelligent buildings, environmental protection, fan and blow risk control, filter and blow risk control, fluid and level control. But many people do not understand the principle and installation method of DWYER differential pressure switch, so what is the principle and installation method of DWYER differential pressure switch?Now, AIXUN will introduce it to you.

DWYER differential pressure switch principle:

The valve body and stroke switch of the DWYER differential pressure switch are assembled on a single baseplate. Under the action of pressure, the grease enters the right chamber of the differential pressure switch valve body piston from the main pipe B, and the main pipe A is unloaded. Once the pressure difference between the two main pipes reaches the set value, the piston overcomes the spring force in the left chamber to move to the left, and pushes the stroke switch, so that contacts 1 and 2 are closed, sends A pulse signal to the system electric control box, orders the reversing valve to reverse, then the main pipe A is under pressure, B is unloaded, the piston is in the center under the action of the spring in the two-end cavity, the stroke switch contacts 1 and 2 are disconnected, and the bridge is in the middle.

Once the pressure difference between the main pipe A and B reaches the set value again, the piston moves to the right, the stroke switch contacts 3 and 4 are closed, and the pulse signal makes the reversing valve in the system reverse again to start the next cycle.

The application of differential pressure switch in HVAC system is mainly controlled according to the resistance and flow curve of HVAC equipment. The water-side heat exchangers in HVAC (sleeve type, shell and tube type, tubesheet type and commonly used plate heat exchangers), water filters, valves and pumps have their pressure drop and flow performance curves. As long as the measured differential pressure on both sides of the differential pressure switch is compared with the pre-set value, the flow rate can be accurately controlled.

DWYER differential pressure switch in general is to use the pressure difference between the two pipes to send a signal, when the pressure difference at the two ends of the series liquid pipe rises (or decreases) and exceeds the set value of the controller, send a signal to control the reversing valve or monitor the lubrication system. The valve is then opened (or closed), so that the pressure difference at the two ends of the system liquid pipe is reduced, and the normal operation of the system is achieved.

DWYER differential pressure switches are widely used to monitor gases, non-corrosive media, and measure absolute, gauge and pressure. Widely used in the following applications, such as: air conditioning and clean rooms, intelligent buildings, environmental protection, fan and blow risk control, filter and blow risk control, fluid and level control.

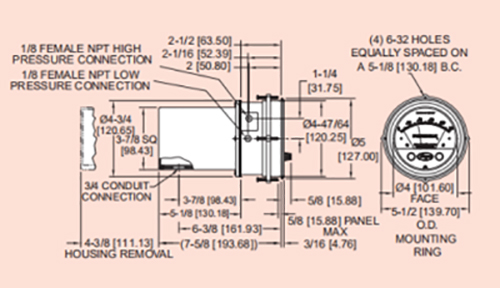

DWYER differential pressure switch installation method:

1, regardless of the same side installation or other methods, it is necessary to take over as short as possible, and the water taken over at one end can be discharged (to prevent freezing).

2. The installation of the differential pressure flow switch requires welding of the pressure measuring interface at the inlet and outlet of the heat exchanger.

3, the inlet water pipe is connected to the "+" end, the outlet water pipe is connected to the "-" end.

4. The pressure measuring tubes and shells on both sides of the differential pressure switch need to be insulated.

5, the differential pressure switch provides SPDT contacts, that is, a normally open and a normally closed contact is available for access to the controller, the factory default leads to normally open contacts.

Wuxi Aixun Automation Technology Co., Ltd. focuses on the production of automation control system, solenoid valve box, valve island bus control box and instrument box, etc. It is also an authorized agent for EMERSON, ASCO, TOPWORX, GOswitch, Numatics, Aventics, Dwyer, GVT, SUNTEX Instruments.Aixun takes integrity as the foundation, quality as the life, and customer as the center! Welcome to inquire!