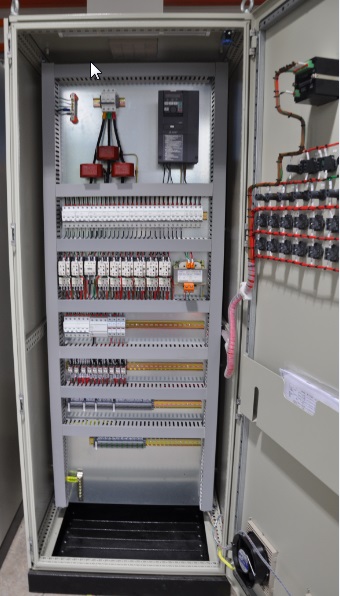

The electrical control cabinet for water treatment in the water plant is an automation control system developed by Wuxi Aixun Automation for the water plant, which provides decentralized control and centralized management of equipment. Composed of motor cabinet, PLC cabinet, on-site IO cabinet, electromagnetic valve box, on-site work box, and upper computer system.

Emerson PLC electrical control cabinet can be programmed only when the switch is turned on by simply changing the code. So, by using PLC control system cabinets, it is easy to merge multiple inputs and inputs. The PLC automatic control system cabinet can also control more complex processes. Emerson PLC electrical control cabinets can be customized according to application programs and user needs.

The PLC automatic control system cabinet includes five parts: rack or chassis, power module, processor (CPU), input/output module, and communication interface module. The power module is used to provide the required power for the entire PLC system. It converts available AC power into DC power required by the CPU and I/O modules. PLCs typically operate on a 24V DC power supply. Few PLCs use isolated power sources. The CPU module CPU module has processors, drivers, and applications. Memory is used to store programs and data. The CPU is the brain of a PLC with an octagonal or hexagonal microprocessor. As other electrical components based on microprocessors, cables used to connect other devices. Input/Output Module - Input devices can be start and stop buttons, switches, etc., and output devices can be electric heaters, valves, relays, etc. Digital modules facilitate the interface between input and output devices and microprocessors.

PLC electrical control cabinets can achieve equipment automation and process automation control, achieve network functions, have stable performance, scalability, and strong anti-interference characteristics, and are the core and soul of modern industry. PLC control cabinets, frequency conversion cabinets, etc. can be customized according to user needs to meet user requirements, and can be paired with human-machine interface touch screens to achieve easy work. The device can also transmit data with communication protocols such as modbus and profibus on the DCS bus upper computer; Control and monitoring implemented by industrial computers, Ethernet, etc.

Wuxi Aixun Automation Technology Co., Ltd. is engaged in automation control design and production processing. For a long time, AIXUN Automation has been in line with the concept of "listening to customer needs, thinking solutions together with customers, and trying to solve problems for customers", serving customers in various industries, in accordance with the modern enterprise management mechanism "honesty as the fundamental, quality as the focus, customer-centric".

Aixun Automation is looking forward to the support of new and old customers as always! Sincerely hope to work with you hand in hand, common development