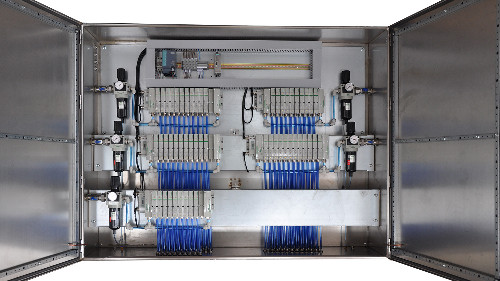

PLC control cabinet - Electrical control cabinet can complete equipment automation and process automation control, achieve network functions, have stable performance, scalability, strong anti-interference characteristics, and is the core and soul of modern industry. PLC control cabinets, frequency conversion cabinets, etc. can be customized according to user needs to meet user requirements, and can be paired with human-machine interface touch screens to achieve easy work. The device can also transmit data with communication protocols such as modbus and profibus on the DCS bus upper computer; Control and monitoring implemented by industrial computers, Ethernet, etc.

VOC waste gas treatment control system - PLC control cabinet! Control mode: on-site manual control mode and remote upper computer control mode of the control cabinet, cabinet shell material: stainless steel PS cabinet.

PLC Control Cabinet - Electrical Control Cabinet Features

(1) Power supply circuit. There are various power sources for the power supply circuit, including AC380V and 220V.

(2) Protection circuit. There are various types of working power sources for protecting (auxiliary) circuits, such as single-phase 220, 36V or DC 220, 24V, etc., which provide various protections for electrical equipment and circuits such as short circuits, overload, and voltage loss. They are composed of protective components such as fuses, thermal relays, voltage loss coils, rectifier components, and voltage stabilizing components.

(3) PLC control cabinet is an electrical cabinet that integrates touch screen, intermediate relay, contactor, power supply, circuit breaker and other electrical components with PLC controller as the core control unit. Customized design according to engineering technical requirements to achieve equipment automation and process automation control.

(4) Control the equipment according to the process requirements, complete the corresponding process flow, and achieve functions such as sequential start stop and interlock protection of the equipment;

Automatically monitor and record equipment process variables, equipment status, and other data, display real-time process flow and process data, and generate reports and records automatically.

(5) PLC control cabinet, with strong anti-interference ability, stable performance, and convenient maintenance.

Wuxi Aixun Automation Technology Co., Ltd. is engaged in automation control design and production processing. For a long time, AIXUN Automation has been in line with the concept of "listening to customer needs, thinking solutions together with customers, and trying to solve problems for customers", serving customers in various industries, in accordance with the modern enterprise management mechanism "honesty as the fundamental, quality as the focus, customer-centric".

Aixun Automation is looking forward to the support of new and old customers as always! Sincerely hope to work with you hand in hand, common development.